Custom Aluminum Signs

What’s the feature of aluminum signs?

Signage has long been an essential part of decor, commerce, and even advertising campaigns. Today, thanks to technology and a wide range of materials available for production, it can be customized to suit any preference.

One of the main advantages of aluminum signs is their light weight and durability. Aluminum, as a material, is exceptionally light, which makes installation easy and prevents excessive strain on the surface it is mounted on. Additionally, thanks to its resistance to corrosion, custom aluminum signage can be used in a variety of environments. Unlike steel, which is prone to rust, aluminum signs can be safely placed outdoors, even in humid climates.

Another advantage of aluminum is its eco-friendliness. It is fully recyclable, making it an ideal choice for companies that prioritize sustainable material use and care about environmental preservation.

Aluminum signs for business are also highly adaptable to printing and finishing processes. Their smooth surface allows easy painting, engraving, printing, or vinyl application. Moreover, aluminum is easy to cut and shape, providing nearly unlimited customization options and the ability to bring almost any design to life.

An advantage of aluminum, particularly for residents of hot or fire-prone regions, is its fire resistance. Aluminum does not support combustion and will not burn, ensuring maximum safety in its use.

Finally, aluminum custom signs are a cost-effective long-term investment. While pricing depends on various factors, even if the initial cost is higher, they help save money on maintenance over time. Aluminum signs require minimal upkeep, making their maintenance both infrequent and affordable.

Types of aluminum signs and which one is better to choose

Aluminum signs come in a wide variety, but five key types can be distinguished among them:

- Flat aluminum signs

- Composite signs (ACM)

- Dimensional letters

- Lightboxes

- Engraved plaques

Let’s take a closer look at each.

Flat aluminum signs are typically sheets of aluminum with a thickness ranging from 0.5 to 3 mm. They can have different coatings: painted, anodized, or laminated. In this case, the image or text is applied using printing, vinyl film, or engraving. The key advantages of flat aluminum signs include their lightweight nature, durability, affordability, and the ability to accommodate printing, painting, or engraving. However, this type of sign is less noticeable, requires rigid mounting to prevent deformation, and some types of printed graphics may fade over time.

Composite signs (aluminum composite material, ACM) consist of two thin aluminum layers, each no thicker than 0.5 mm, with a polymer core, usually made of polyethylene or a non-combustible filler. The benefits of this type of aluminum sign include rigidity (they don’t bend or warp), longevity, a wide variety of textures and colors, and compatibility with various image/text application methods. However, they are harder to shape, and in cheaper options, the polyethylene core can be flammable.

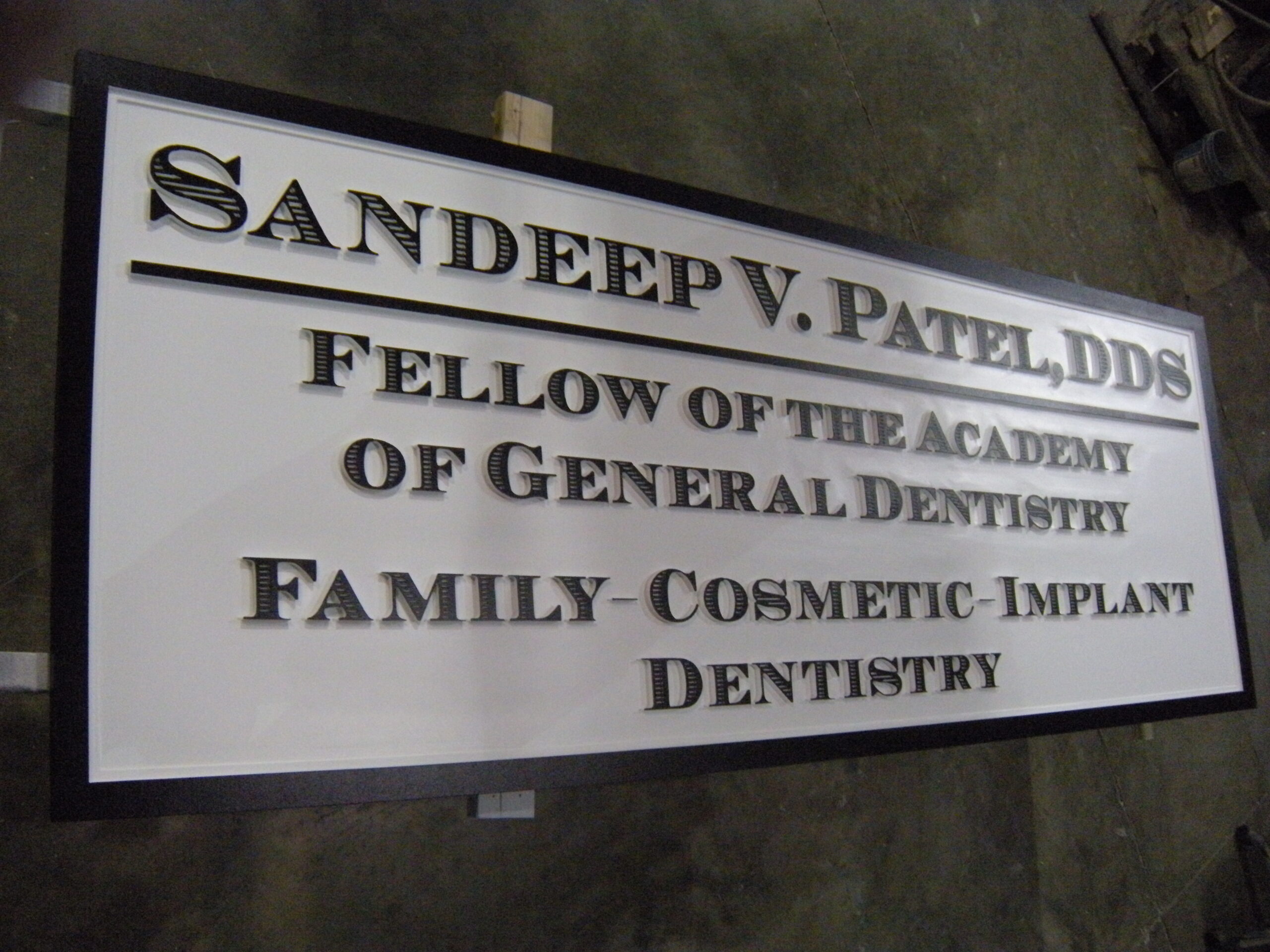

Dimensional letters are made from aluminum profiles or cut from thick aluminum sheets. They can be produced with or without backlighting. This is a highly visible type of signage that has a prestigious look and is known for its durability. However, it comes with a high price tag, is complex to install, and is heavier than flat signs, requiring a reliable mounting base.

Lightboxes have an aluminum frame and typically consist of three parts:

- An aluminum profile

- LED backlighting

- A front panel

The key advantages of lightboxes include high visibility at night, a modern appearance, a wide range of design options, and durability. However, they require electrical power and regular maintenance, such as cleaning or replacing lamps.

Engraved plaques are made from plates no thicker than 2 mm, with engraving applied either by laser or mechanically. They can be coated with paint or anodized for additional protection. This is a long-lasting option that withstands environmental factors and has a sleek, understated look. Unfortunately, the color palette is limited.

How to make custom aluminum signs?

The first step is finalizing the design of the sign. Customers can either provide their design or receive a proposal from the company’s qualified designers. At this stage, all details are clarified, from the sign dimensions to the type of finish.

Next, it is determined whether the sign will be made entirely from aluminum sheets or if composite materials, acrylic, or PVC need to be added. Acrylic and PVC are typically used for lightboxes (as front panels) or as additional decorative elements.

The following stage involves cutting. This can be done using laser cutting, which ensures precise lettering, graphics, and intricate details, or CNC routing, which is used for producing three-dimensional components. At this step, engraving can also be used, which can be performed either by laser or mechanical methods.

After cutting, the sign undergoes coating and finishing. The available options include:

- Anodizing, which protects the sign from corrosion and enhances its appearance.

- Powder coating, which adds color and texture to the surface.

- Brushing which gives the aluminum a matte, satin-like finish.

- Polishing creates a mirror-like effect for a sleek and sophisticated look.

An additional step, if required, is applying printed elements to the sign. This is typically done using UV printing, for bright and detailed images on flat surfaces, vinyl decals, or photo printing, especially for large images or advertising signs.

What technologies are used to create aluminum signs?

The technology used to manufacture custom-made aluminum signs depends on their design. For example, if the sign has intricate shapes and contours, laser cutting technology is applied. If the sign includes lighting, LED backlighting is also incorporated.

In general, there are eight key technologies commonly used in custom printed aluminum signs manufacturing:

- Laser cutting is performed by cutting aluminum with a laser beam at high temperatures.

- CNC routing is done using a milling machine that cuts the material into the desired shape.

- Engraving is divided into two types: mechanical and laser. The first requires tools that physically cut into the metal surface, while the second creates precise designs using a laser beam.

- Anodizing is an electrochemical process that converts the aluminum surface into an oxide layer, providing protection.

- Powder coating applies a colored finish to the sign’s surface using an electrostatic charge, after which the powder is cured in a high-temperature oven.

- UV printing allows images to be applied using ultraviolet rays, with the ink drying almost instantly.

- Water jet cutting uses a high-pressure stream of water to cut materials and create complex shapes.

- LED backlighting utilizes either LED strips or individual LED bulbs.

Although each item on this list belongs to a different category of technology, together they form the most relevant selection of processes typically used in printed aluminum signs manufacturing. In most cases, multiple technologies from the list are combined to create a single product. It all depends on the design.

Where better to use aluminum signs?

Aluminum signs stand out for their durability, resistance to weather conditions and external factors, and aesthetic appearance, making them highly versatile.

For example, they look great on building facades. Whether it’s a café, restaurant, store, hotel, or business center, aluminum business signs serve as an elegant addition to any exterior. This is especially true if they are designed as illuminated 3D letters or sleek, flat plaques. They withstand sun exposure, rain, and wind, ensuring a long service life even in outdoor conditions.

Aluminum signs are also well-suited for street information boards and navigation signs. They are lightweight, durable, and remain clearly visible even in harsh weather conditions. This makes them ideal for parking lots, roads, parks, and tourist route markings. They are also commonly used in airports, shopping malls, hospitals, and other public spaces.

Office nameplates, often used to mark individual rooms, are frequently made of aluminum as well. Their sleek design adds a touch of sophistication to the interiors. Additionally, aluminum custom signs are an excellent choice for personal nameplates, whether for apartment doors, houses, or personal workspaces. They are also popular as decorative elements in restaurants, cafés, pubs, and even private homes.

Thanks to their resistance to chemical exposure, temperature fluctuations, and mechanical damage, custom aluminum business signs are well-suited for industrial use, such as in factories, warehouses, and production facilities.

In other words, aluminum signs offer a wide range of applications, withstand outdoor conditions exceptionally well, and add an elegant touch to any interior.

What’s the cost of custom aluminum signs?

Custom-made aluminum signs offer a unique opportunity to create signage that enhances a brand’s distinctive style, strengthens its presence, and boosts recognition. This allows businesses to design a sign that perfectly aligns with their needs. But how much does this cost?

Custom aluminum safety signs are considered one of the most affordable options among metal signs. They stand out for their durability, weather resistance, and aesthetic appeal. However, several factors influence the final price of an aluminum sign.

The first key factor is the type of aluminum:

- Anodized aluminum

- Painted aluminum

- Raw sheet aluminum

Anodized aluminum is the most expensive due to its additional processing and corrosion protection. Painted aluminum comes next in price — it is more affordable but less durable. The most budget-friendly option is raw sheet aluminum, as it requires no extra treatment.

The thickness of the material and the size of the sign also impact the price. The thicker the aluminum sheet, the higher the cost. The same applies to size — the large aluminum signs are more expensive than the small ones.

Another factor affecting pricing is the method used to apply text or images. For example, engraving ensures long-lasting results but can be costly. Printing is a cheaper option, though it may wear out over time.

Additional elements and technologies — such as lighting, glass, acrylic, or CNC milling — also influence the price. Each of these features can raise costs depending on quantity, complexity, or simply their inclusion.

The final cost is also affected by order quantity. Providing a fixed price for a custom-made aluminum sign is impossible, as it depends on the design’s complexity and dimensions.

Custom aluminum signs near you

A custom aluminum sign is a type of signage that requires careful consideration when you choose it, as multiple factors influence its quality, durability, and cost.

When choosing a company for custom aluminum signage, there are several factors to consider:

- Experience and reviews

- Personalized approach to the order

- Pricing structure

- Production time

- Availability of additional services such as delivery, support, etc.

- Warranty and service

- Compliance with regulatory requirements

By focusing on these factors, it will be easier to make an informed decision and choose a professional manufacturer that will create a high-quality product.

Not sure if you need an aluminum sign?

Aluminum signs are an aesthetic solution, but not always the most optimal. For example, expanded polystyrene (EPS) signs offer advantages that make them a more cost-effective choice than aluminum signs.

First and foremost, EPS stands out due to its lightweight nature. This is an important benefit when it comes to installation, as EPS signs are easier and significantly quicker to install.

Moreover, EPS signs are generally more affordable, allowing for savings on the order. They are also more flexible in design and easier to customize, allowing for intricate shapes and details that would be impossible to create with metal. EPS can also be painted and covered with various decorative materials, expanding creative possibilities and not limiting imagination.

An equally important factor is EPS’s resistance to weather conditions, environmental influences, and thermal protection. This allows for installation in any location and climate.

So, if you’re unsure or don’t have an urgent need for aluminum signs, EPS signs are a more beneficial alternative. One of the experienced companies specializing in custom EPS signage is our 3D Sign Factory.

3D Sign Factory is a sign manufacturing company operating since 1990. We serve about 800 clients each year, creating signs for businesses, restaurants, hotels, churches, public spaces, exhibitions, and more.

Partnering with us ensures that the final product will meet expectations. We are committed to delivering not only first-class service but also high-quality execution of every order.

Our specialists help clients choose the best option that meets all their requirements. Additionally, we are highly flexible and can adapt a project to fit the client’s technical specifications if needed. Our specialists thoroughly inspect the final product to ensure it meets all necessary quality standards and guarantees long-lasting durability. We deliver every order pre-assembled, saving both time and costs on on-site installation.

Even if a client is unsure whether a particular option fits their budget, we can adjust the project’s cost or offer a more affordable yet equally suitable alternative. We also provide long-term warranties on all our products, and to make future interactions easier, we keep a record of every project for 25 years after production.

Moreover, we are an environmentally responsible and sustainable signage company that uses only eco-friendly materials and modern energy-efficient technologies. We rely on innovative solutions, integrating advanced technology and creative approaches into our production processes.

We are always open to new partnerships and challenges, ready to bring almost any idea to life.

For a free quote, call 904-345-5400 or fill out the form with the link.

Aluminum Signs FAQ

What kind of aluminum are street signs made of?

Road signs are usually made from aluminum, which is resistant to corrosion and known for its durability and strength.

Are street signs aluminum?

Yes, street signs are made from aluminum, which is known for its durability against weather conditions and external factors.

How to make aluminum signs?

First of all, to make an aluminum sign, you need to determine its size and design. If you don’t have the opportunity or inspiration to create your own design, some manufacturing companies offer the services of their designers, who can help create a version that meets all the requirements.

How to make custom aluminum signs?

You need to develop a design that meets your needs or the needs of your brand. Afterward, you will need to approve it and coordinate the subsequent production processes with the manufacturer.

What factors influence the price of aluminum signs?

Pricing depends on the size and thickness of the product, the complexity of the design, the method of image or text application, the presence of additional decorative or lighting elements, the type of coating, and the complexity of the installation.

What is the standard thickness of the aluminum sheet for aluminum signs?

The typical thickness of regular aluminum sheet used for making signs ranges from 0.5 to 3 mm.

What is the lifespan of custom aluminum signage?

The average lifespan of an aluminum sign is around 10 years. However, it can vary depending on the conditions in which the sign is placed and how well it is maintained.

Is it okay to use an aluminum sign outdoors?

Yes, aluminum signs are known for their durability and resistance to weather conditions, making them perfect for outdoor use.

Does 3D Sign Factory provide delivery for its products?

Yes, we offer delivery of our products and also provide the option of free storage of the order at our warehouse if the customer is unable to pick it up immediately after production.

Can aluminum signs corrode over time?

No, aluminum is naturally resistant to rust, and when a protective coating is applied, its resistance to weather conditions is further enhanced.

Does 3D Sign Factory offer a warranty for its products?

Yes, we offer a multi-year warranty on our products and provide support after the order is completed.

Where is better to order an aluminum sign?

It is best to order the sign from a manufacturer like us, as this ensures direct communication with the producer without any intermediaries and quick turnaround times for preparing estimates.